The Process of Ceramic Coating Application

How to Achieve a Durable, Glossy Finish

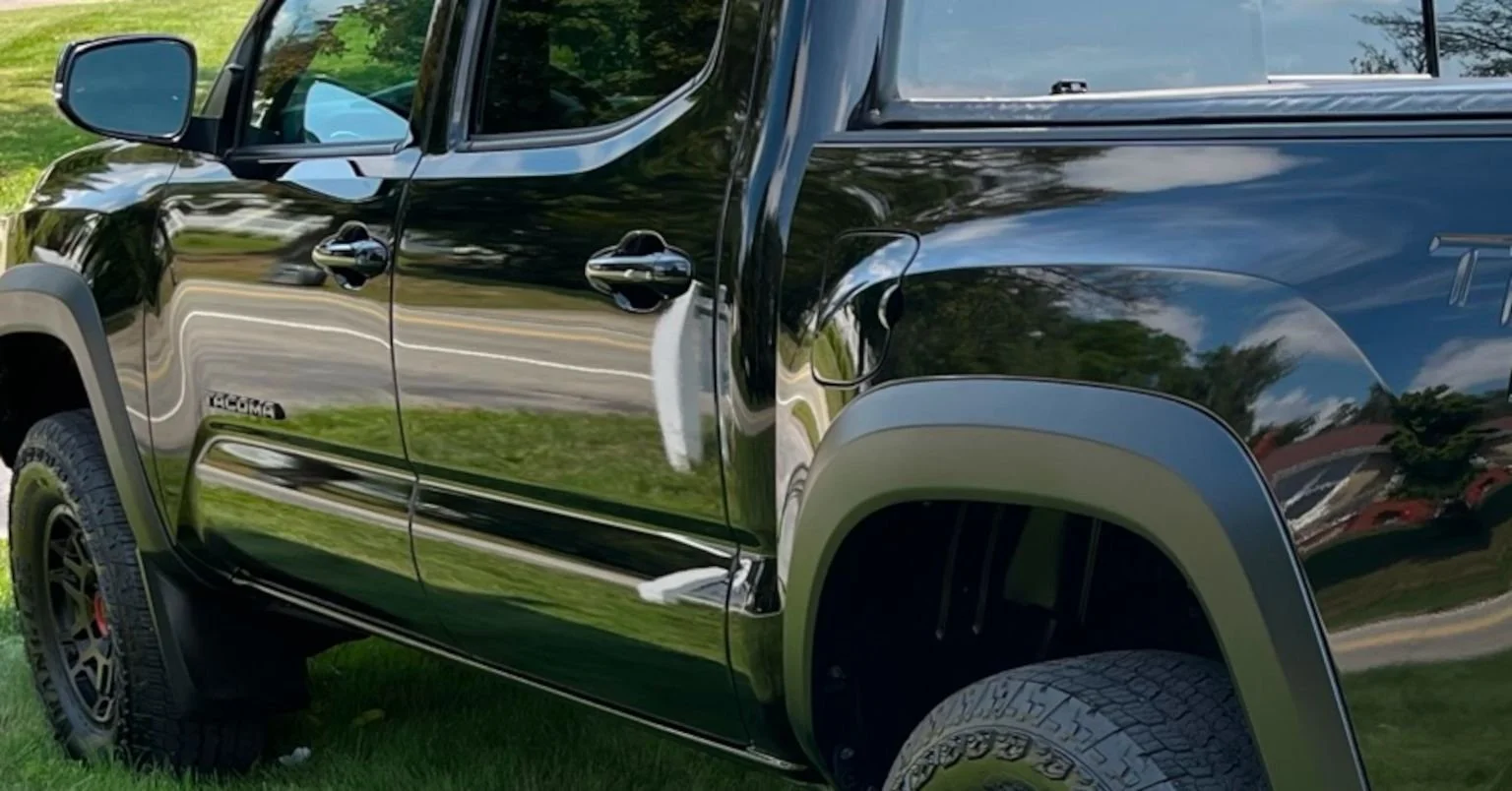

In recent years, ceramic coatings have become the gold standard for vehicle protection. This advanced technology provides a resilient, glossy shield that helps keep your car looking pristine by protecting it from environmental damage, UV rays, and minor scratches. But what exactly is the ceramic coating process, and how do professionals achieve such a flawless, long-lasting finish? In this guide, we’ll break down the steps involved and offer insights on how to apply ceramic coatings effectively.

What is a Ceramic Coating?

A ceramic coating is a liquid polymer solution that chemically bonds with a vehicle's paint to create a durable layer of protection. Composed primarily of silicon dioxide (SiO2), the coating forms a transparent, hydrophobic shield that repels water, dirt, and contaminants, while enhancing your car’s gloss and making it easier to maintain. Ceramic coatings last far longer than traditional waxes or sealants and are popular among car owners who want enhanced protection for their investment.

The ceramic coating process involves a series of meticulous steps that ensure the coating bonds effectively with the vehicle’s surface. While some vehicle owners attempt to apply ceramic coatings themselves, a professional application delivers the best results, as it requires precision and attention to detail.

Step-by-Step Guide to the Ceramic Coating Process

The ceramic coating process typically includes four main steps: preparation, application, curing, and maintenance. Each step is essential to achieving a durable, high-gloss finish that can stand up to the elements.

1. Preparation: Clean and Decontaminate the Surface

Preparation is the foundation of a successful ceramic coating application. To ensure a strong bond, the vehicle’s surface must be thoroughly cleaned and decontaminated. Here’s how professionals prepare a vehicle for ceramic coating:

Wash the Car: Begin by washing the vehicle with a pH-neutral soap to remove dirt, grime, and any previous wax or sealant. Using the two-bucket method helps minimize the risk of introducing scratches during the wash.

Clay Bar Treatment: After washing, a clay bar treatment is used to remove embedded contaminants that regular washing can’t eliminate. This step leaves the paint smooth and free of impurities, which is crucial for the coating to bond effectively.

Iron Remover: An iron remover spray is often applied to eliminate any remaining metal particles or brake dust that might be present on the paint. These particles can compromise the coating's adhesion, so it’s essential to remove them before application.

Paint Correction (If Necessary): If the paint has visible scratches, swirl marks, or oxidation, a paint correction process may be necessary. Using a dual-action polisher and polish compounds, detailers carefully restore the paint to a flawless finish. Any imperfections left untreated can become more noticeable once the coating is applied, so it’s worth taking the time to achieve a perfect base.

2. Application: Applying the Ceramic Coating

Once the car is clean, decontaminated, and the paint is corrected, it’s time to apply the ceramic coating. Here’s how to apply ceramic coatings for the best results:

Section-by-Section Application: The coating is applied in small sections to ensure even coverage and prevent the product from drying out. Using an applicator pad, the detailer applies a thin layer of ceramic coating to each section, typically working on one panel at a time.

Crosshatch Pattern: To ensure complete coverage, the coating is applied in a crosshatch pattern—first horizontally, then vertically. This technique helps achieve uniform coverage, ensuring that no areas are missed.

Buff Off Excess Product: After a short curing time (usually a few minutes, depending on the product), the excess coating is gently buffed off using a microfiber towel. Buffing removes any excess product and helps avoid streaks or haziness. The detailer will inspect each section before moving on to the next to ensure an even, glossy finish.

Multiple Layers (If Desired): Some ceramic coatings allow for additional layers to be applied for extra durability and depth. If multiple layers are being applied, there is a specified waiting period between coats, as indicated by the manufacturer.

3. Curing: Allowing the Coating to Harden

The curing stage is a crucial part of the ceramic coating process. Once the coating is applied, it needs time to bond fully with the paint.

Initial Cure: Right after the application, the coating begins to cure, but it’s still vulnerable. It’s essential to keep the car in a controlled environment, away from dust, moisture, and direct sunlight during this time.

Full Curing Period: Most ceramic coatings reach their full hardness after 24 to 48 hours. During this period, it’s important not to expose the vehicle to water, extreme temperatures, or contaminants. Some professional detailers use infrared curing lamps to speed up the curing process, especially in colder climates.

Avoid Washing: It’s recommended to avoid washing the vehicle for at least a week after the coating application to allow it to reach maximum durability.

4. Maintenance: Keeping Your Ceramic Coating in Top Shape

One of the benefits of ceramic coatings is that they require minimal maintenance, but there are still steps you can take to maximize the lifespan of the coating. Here’s how to care for your ceramic-coated vehicle:

Regular Washing: Wash the car regularly using a pH-neutral soap and the two-bucket method. Avoid automatic car washes, as their abrasive brushes can damage the coating.

Use a Ceramic Coating Maintenance Spray: Ceramic coating maintenance sprays can help rejuvenate the coating’s hydrophobic properties, ensuring that water continues to bead up and roll off the surface. These sprays also enhance the coating’s shine and provide additional protection.

Avoid Harsh Chemicals: When cleaning your ceramic-coated car, stick to gentle products. Harsh chemicals can break down the coating over time, reducing its effectiveness.

Inspect for Wear: Depending on the product, ceramic coatings can last anywhere from one to five years. Regularly inspect the coating for signs of wear and consider reapplying or touching up areas if needed.

Benefits of Professional Ceramic Coating Application

Applying ceramic coating is a meticulous process, and while DIY kits are available, professional application offers several benefits:

Expert Knowledge: Professionals understand the nuances of the ceramic coating process and can customize the application to fit your vehicle’s needs, ensuring a flawless finish.

High-Quality Products: Professional detailing shops often use advanced ceramic coatings that aren’t available to the general public. These products are designed to deliver superior durability and protection.

Time-Saving Convenience: The ceramic coating process can take several hours or even a full day. By leaving it to the experts, you save time and effort while enjoying top-notch results.

Enhanced Longevity: When applied professionally, ceramic coatings last longer and perform better, providing you with a better return on your investment.

Conclusion

The ceramic coating process is a transformative way to protect your car’s exterior, keeping it shiny, sleek, and protected from everyday hazards. From the meticulous preparation to the precision of application and curing, each step plays a vital role in creating a strong, long-lasting bond. At Hanson’s Auto Detail, we’re committed to delivering exceptional results with our professional ceramic coating services. With our experience, certification, and use of industry-leading products, we ensure your car receives the highest level of care.

Ready to enhance your vehicle’s protection and appearance? Contact us today to schedule an appointment or learn more about how to apply ceramic coatings effectively with the help of our expert team. We’re here to help you invest in a finish that will keep your car looking its best for years to come!